Insight:

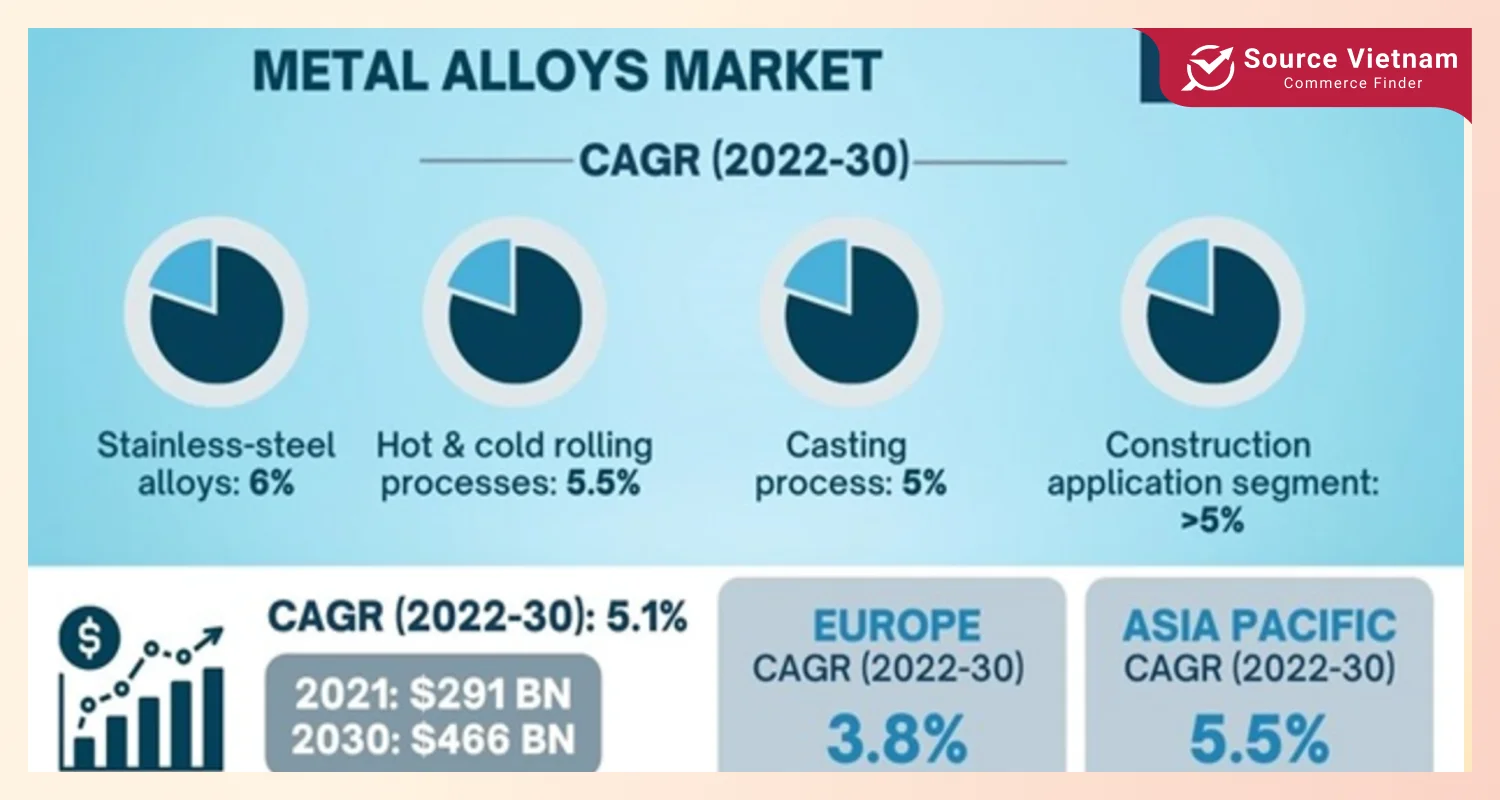

- The metal alloys market was valued at $291 billion in 2021 and is projected to reach $466.27 billion by 2030, with a CAGR of 5.1%.

- Industries like transportation and construction are key drivers, with aluminium alloys expected to generate $229 billion by 2030.

According to accurate market estimates, the metal alloys industry had a worth of $291 billion in 2021, and it is expected to rise further to $466.27 billion by the year 2030. This shows a compound annual growth rate of 5.1% for the industry. Strength, corrosion resistance, and versatility are some of the alloy characteristics which drive the demand in key industries such as construction and transportation.

Metal alloys market overview

The metal alloys market was calculated to be worth $291 billion in the year 2021. The market outlook looks brighter as a report shows that the market revenue will grow at a rapid pace. The compound annual growth rate (CAGR) is 5.1%, which means that from 2022 to 2030, it will reach $466.27 billion. The report claims that the volume is also expected to increase at 4.5% CAGR, reaching quite an amount of 170,031.0 kilotons by the year 2030.

Key drivers and opportunities

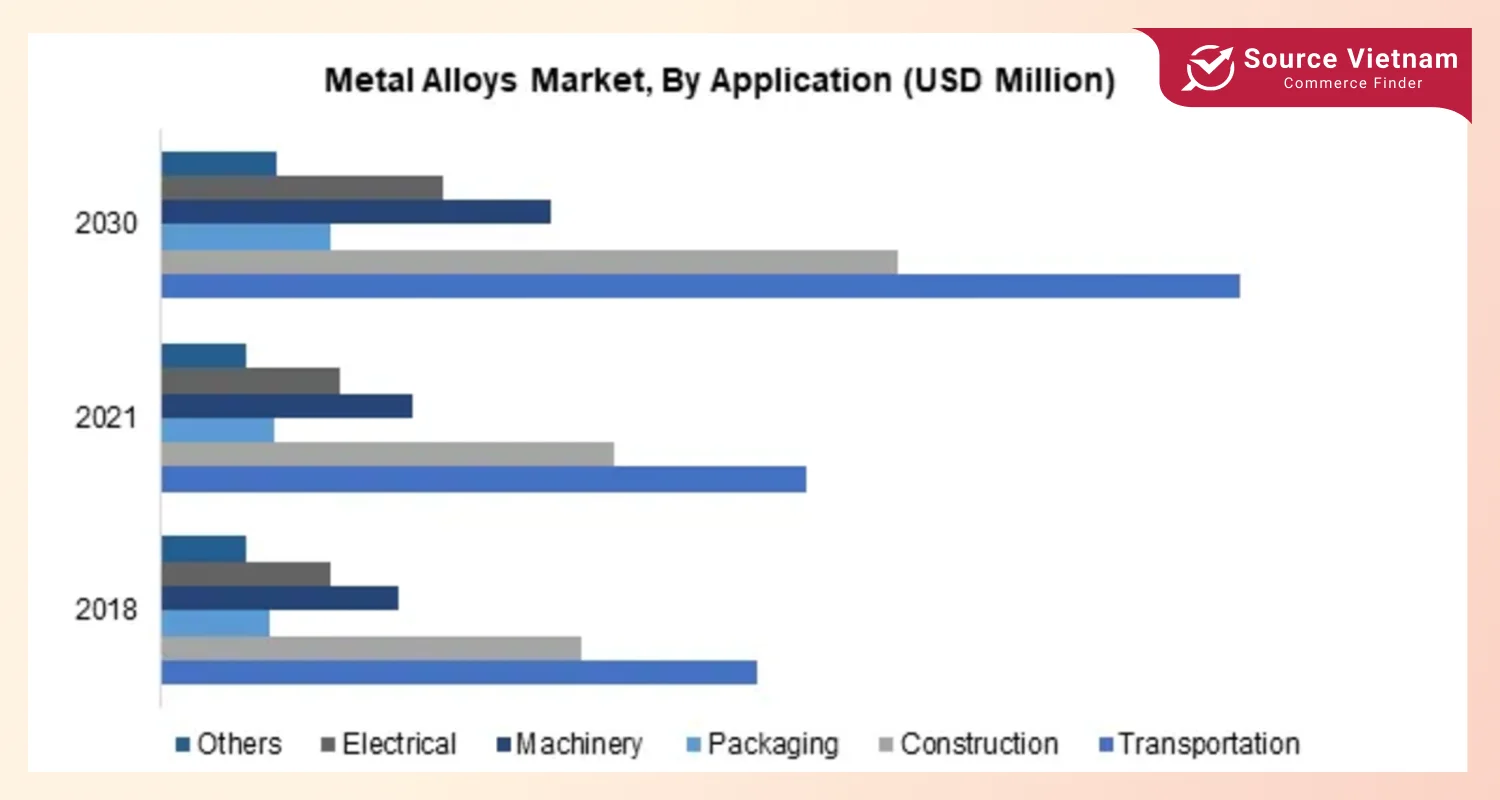

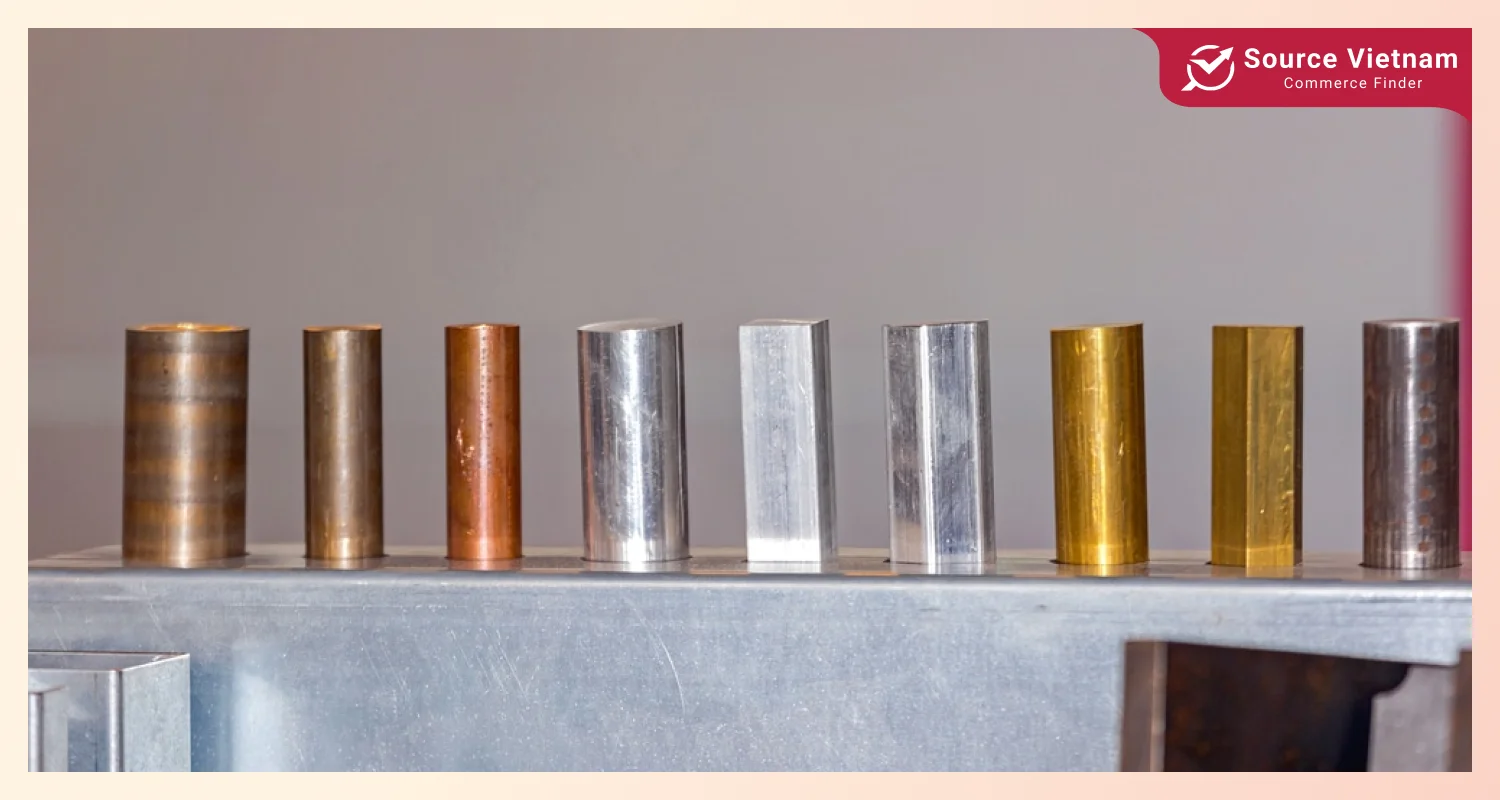

The transportation sector is rapidly expanding, and investments in construction projects are increasing globally. These are the main drivers for the growth of the metal alloys market. Additive manufacturing advancements and growth in flexible packaging are opening new opportunities for the market. Metal alloys are created by combining two or more metals, or a metal and a non-metal, to enhance characteristics such as strength and hardness. These properties make them ideal for transportation, construction, machinery, and packaging applications.

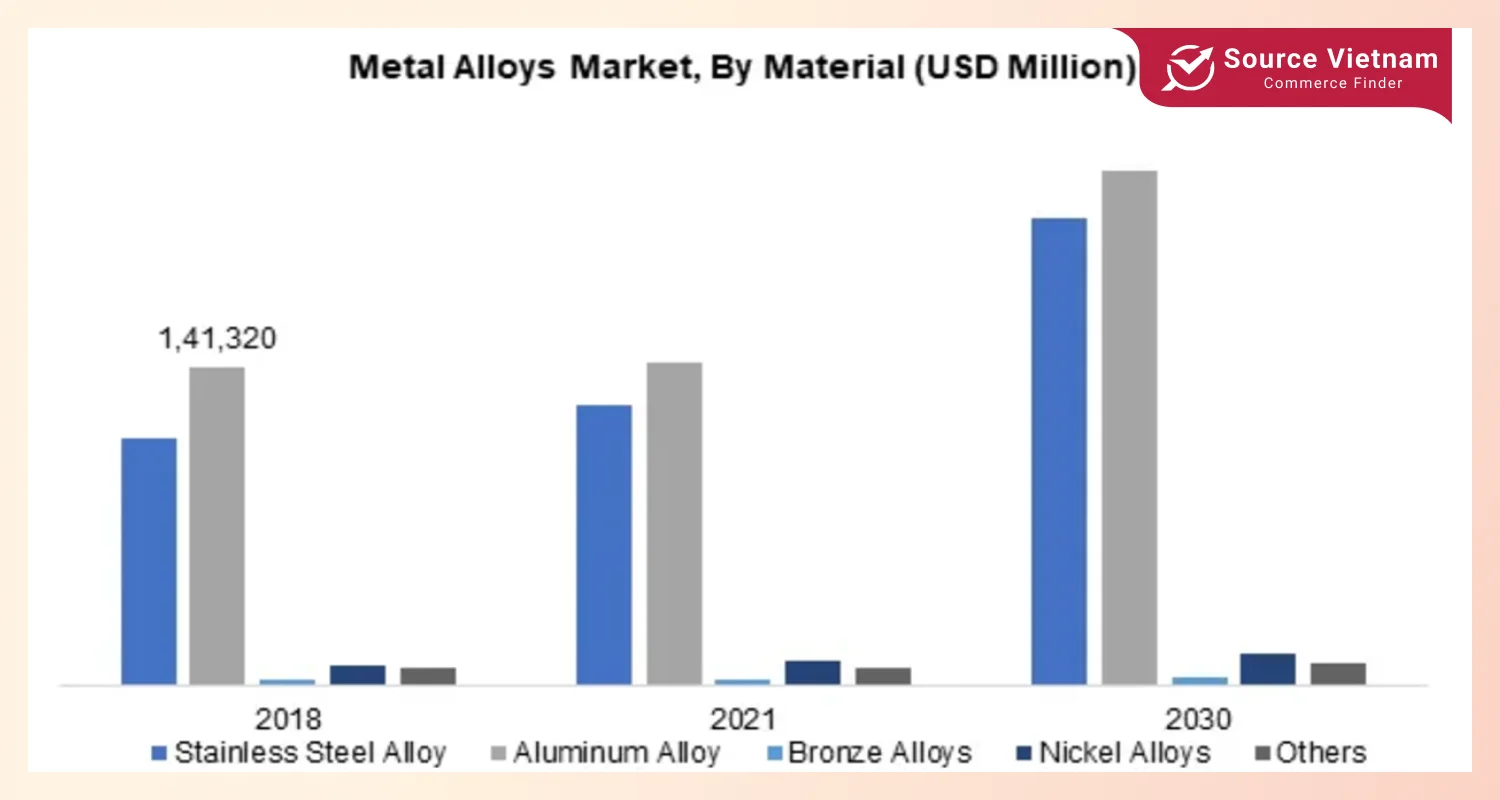

Material insights

- The materials of choice are stainless steel and aluminium alloys on account of their high resistance to environmental factors, strength, and good thermal properties.

- The revenue generated from the aluminium alloy segment is estimated to be around $229 billion by 2030 and is expected to grow at a CAGR of 4.5%.

- Due to their lightweight and sustained use, aluminium alloys find usage in the automotive, aerospace, and construction sectors.

Process insights

- The activity casting process is projected to expand at a CAGR of almost 5% between the years 2022 and 2030.

- Transportation, machinery, and construction industries employ casting to make parts of complex shapes.

- Increasingly, for such products as power tools and sporting goods, magnesium alloy casting is used for transportation.

Application insights

The transportation sector held a 36% volumetric share in 2021, generating over $180 billion in revenue by 2030.

- Lightweight vehicles like LCVs and passenger cars drive demand, especially in North America and Europe.

- Rising fuel prices and stringent emission regulations are encouraging the use of aluminium in automotive applications.

The construction industry is another major consumer of metal alloys. Products like structural sections, girders, rods, and wires are essential in bridges, highways, and buildings.

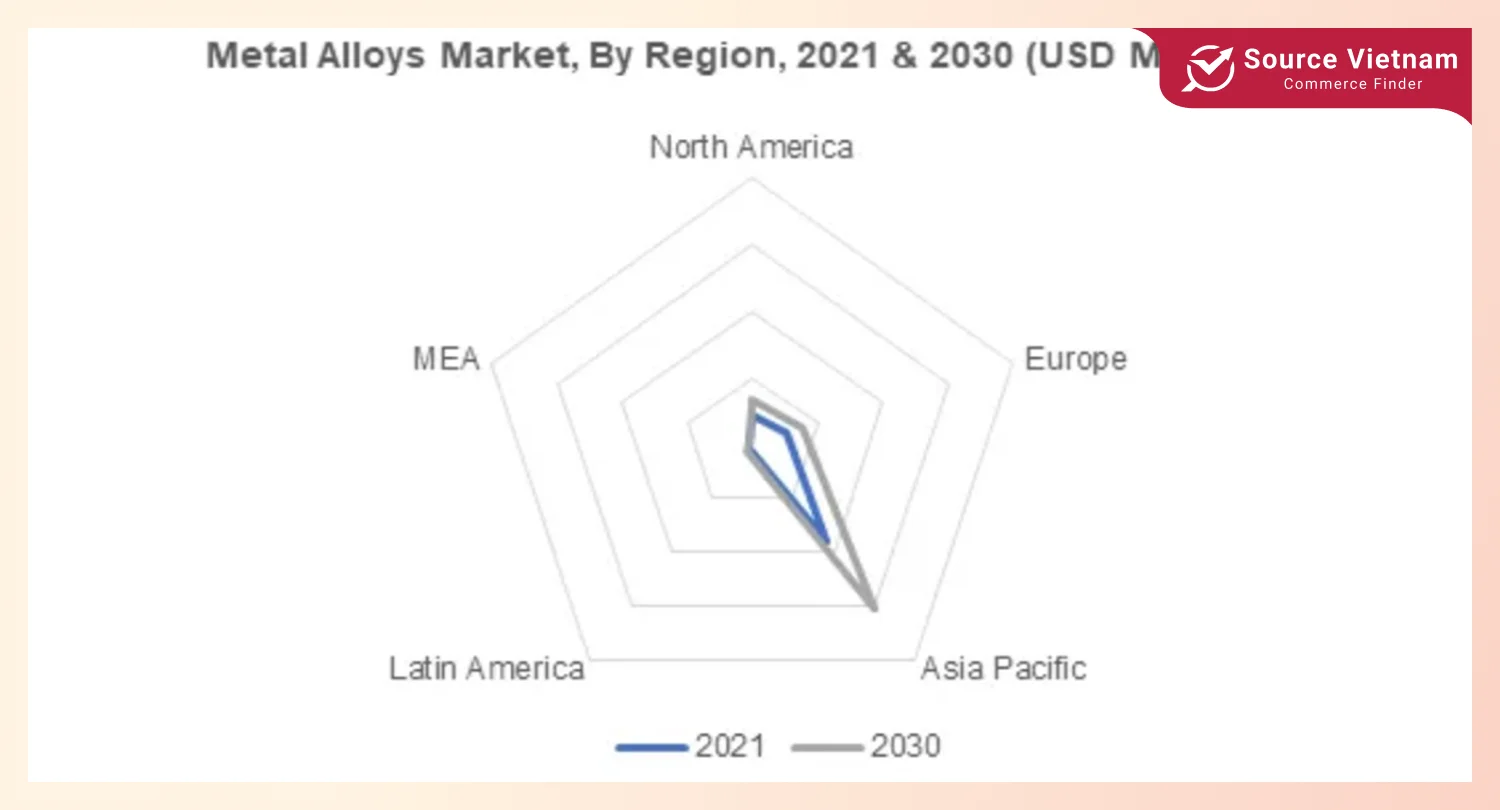

Regional insights

- The Europe metal alloys market generated $52 billion in revenue in 2021 and is expected to grow at a CAGR of 3.8% through 2030.

- Increasing use of aluminium in automotive, shipbuilding, and railway applications supports growth.

- Housing campaigns and growth in flexible packaging are contributing to demand.

Key market players

Major companies in the metal alloys market include:

- RUSAL

- Chalco

- Jindal Stainless

- ArcelorMittal

- POSCO

- Kobe Steel, Ltd.

- Alcoa Corporation

- Rio Tinto

In February 2022, RUSAL developed an optimized 5xxx series aluminium alloy for anodizing at its Bratsk Aluminum Smelter.

Market segmentation

By material

- Stainless Steel Alloys

- Aluminum Alloys

- Bronze Alloys

- Nickel Alloys

- Others

By process

- Casting

- Hot & Cold Rolling

- Others

By application

- Transportation

- Construction

- Packaging

- Machinery

- Electrical

- Others

By region

- North America: U.S., Canada

- Europe: Germany, France, Italy, Spain, UK, Russia

- Asia Pacific: China, India, Japan, South Korea, Australia, Malaysia

- Latin America: Brazil, Mexico

- Middle East & Africa: Saudi Arabia, South Africa, UAE

Research and development

Ongoing R&D is focused on improving metal alloys for diverse environmental conditions. Collaborations between manufacturers and universities are creating new opportunities.

- In April 2020, researchers from Collins Aerospace, Pratt & Whitney, and the University of Connecticut developed new aluminium binary alloys.

- In June 2021, Sandvik Materials Technology studied nickel-based alloys with Lund University scientists.

The metal alloys market is poised for strong growth, driven by innovations and expanding applications across industries.

Conclusion

Rising demand across multiple sectors ensures the metal alloys market will grow to $466.27 billion by 2030. Aluminium and stainless steel alloys remain key contributors, with advancements in manufacturing processes driving future opportunities.