Insight:

- The machinery market is growing steadily, driven by increasing automation, technology adoption, and rising demand.

- However, challenges like intense competition, strict regulations, and rapid technological advancements pose business hurdles.

Industrial machinery refers to machines or a group of machines powered by engines. They are used in various industrial activities to cut, shape, press, roll, or combine these processes. These machines cannot be moved by hand while operating.

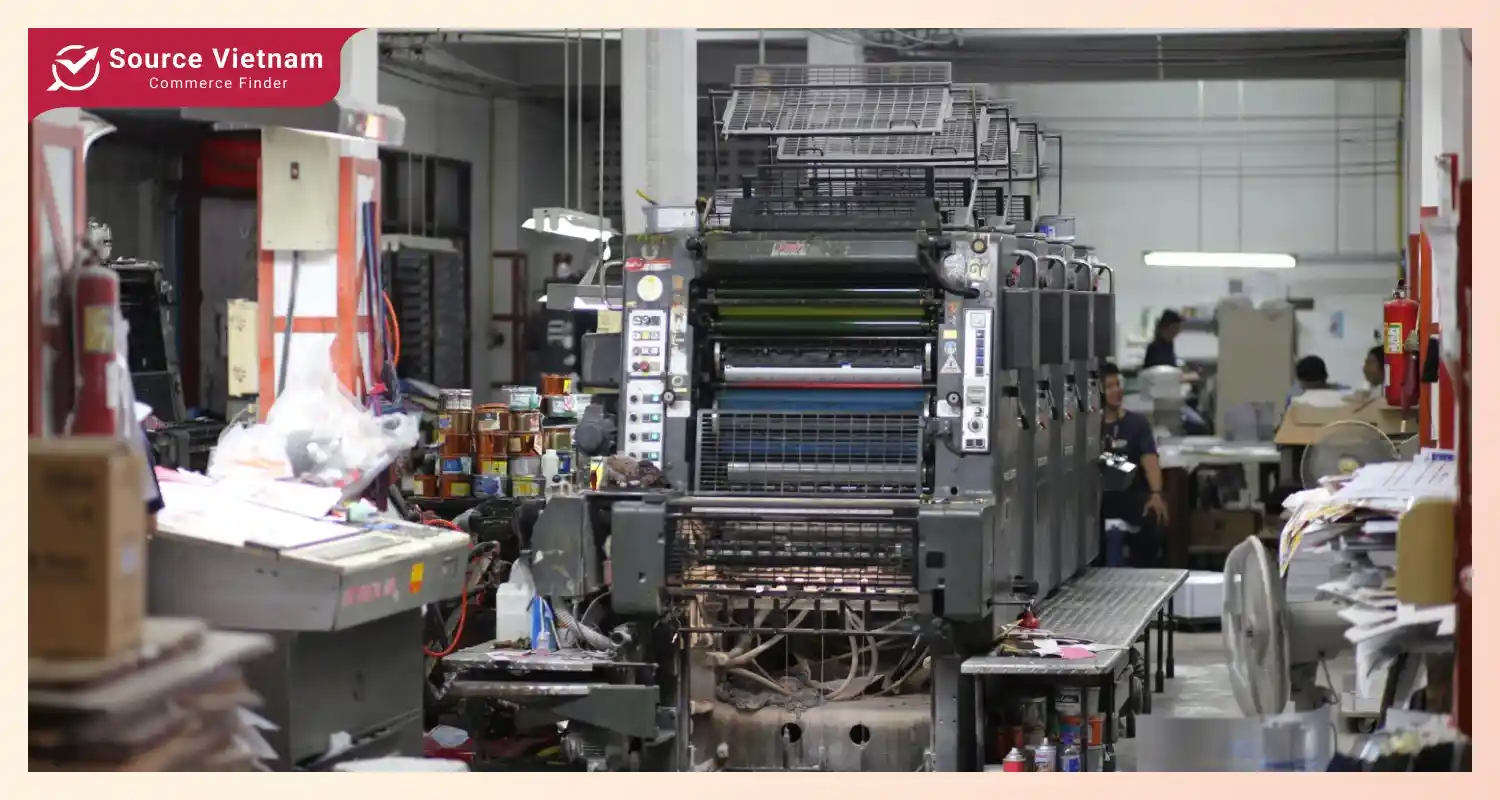

The main types of industrial machinery include wood and paper processing machines, other industrial machinery, printing and printing equipment, semiconductor machines, and food processing machines. Machines that process wood and paper are essential for working with these materials. Operations can be automated, semi-automated, or manual on a small, medium, or large scale.

Latest updates on the industrial machinery market

According to forecasts, the global market for industrial PCs may reach up to $11.83 billion by 2032, with a compound annual growth rate (CAGR) of 9.63% from 2022 to 2032. The industrial machinery sector has experienced robust growth recently. Projections indicate it will rise from $546.76 billion in 2023 to $589.34 billion in 2024, reflecting a CAGR of 7.8% during those years.

The last increase may be attributed to the manufacturing sector development and general economic expansion. The growing use of IoT, big data, and machine learning (ML) in diverse sectors such as manufacturing, oil and gas, automotive, and food and beverage is anticipated to propel the expansion of the global industrial PC market.

There’s a significant shift in data and its value related to IT operational performance. Industry 4.0, a period of transformation and growth, creates a huge demand for computing systems that are flexible in function and capability.

A prime example of such a demand is the integration of IoT, connecting with machines. Consequently, the growing demand from various sectors for energy-efficient production methods is boosting the expansion of the industrial PC market.

Today, Industrial PCs are also used as local or edge-level frameworks for encapsulating individual tasks. Industries such as solar and wind energy, aviation, transportation management, and industrial automation are seeing a significant rise in the use of industrial PCs thanks to their high performance and energy efficiency. Furthermore, manufacturers are motivated to create and launch upgraded versions as different end-user sectors increasingly rely on these devices.

Thanks to the increasing adoption of computers in the production processes by manufacturing companies the investment of Auriga in the industrial PC market will be substantial. Industrial PCs allow manufacturers to track and evaluate their activities in real-time, operationally diagnose problems, and analyze profitability. These measures have integrated several technologies worldwide to facilitate advanced technology movement in the manufacturing sector. This is driving the growth of the industrial PC market.

Industrial machinery market segmentation

The industrial machinery sector encompasses a wide range of equipment that can be utilized across various industries. The report also classifies the market into operation, type, and capacity. Analyzing these segments allows businesses to identify market trends, uncover growth opportunities, and make informed decisions.

The report segments the industrial machinery market in the following ways:

- By type: woodworking and paper machinery, printing machinery and equipment, semiconductor machinery, food processing machinery, and other industrial machinery.

- By operation: automated, semi-automated, manual.

- By capacity: small, medium, large.

The industrial machinery market is categorized by function as follows:

- Wood and paper processing machinery: this machinery is utilized in making wood, paper, and various wood products like furniture, newspapers, and packaging materials.

- Chemical processing machinery: this category includes equipment for producing chemicals and related accessories.

- Glass manufacturing machinery: this type produces glass products such as bottles, windows, and other household items.

- Petroleum refining machinery: these are the tools for refining crude oil into usable petroleum products.

- Plastics processing machinery: this machinery is essential for creating packaging, household goods, and plastic parts.

- Rubber processing machinery: used within the rubber industry, this equipment helps manufacture tires and other industrial rubber products.

- Leather processing machinery: this category involves machines used in the tanning process to create leather goods.

- Textile machinery: this machinery is focused on fabric production within the textile industry.

Other industrial machinery includes machines that don’t fit the categories above, serving diverse industrial needs.

- Printing machinery and equipment: this encompasses a variety of printing machines, including offset, flexographic, and gravure types.

- Semiconductor processing machinery: the equipment in this group is vital for producing semiconductor chips and electronic components.

- Food processing machinery processes food items, including dairy, bakery products, meats, and poultry.

The future of the machinery market

Adapting to the evolving manufacturing landscape

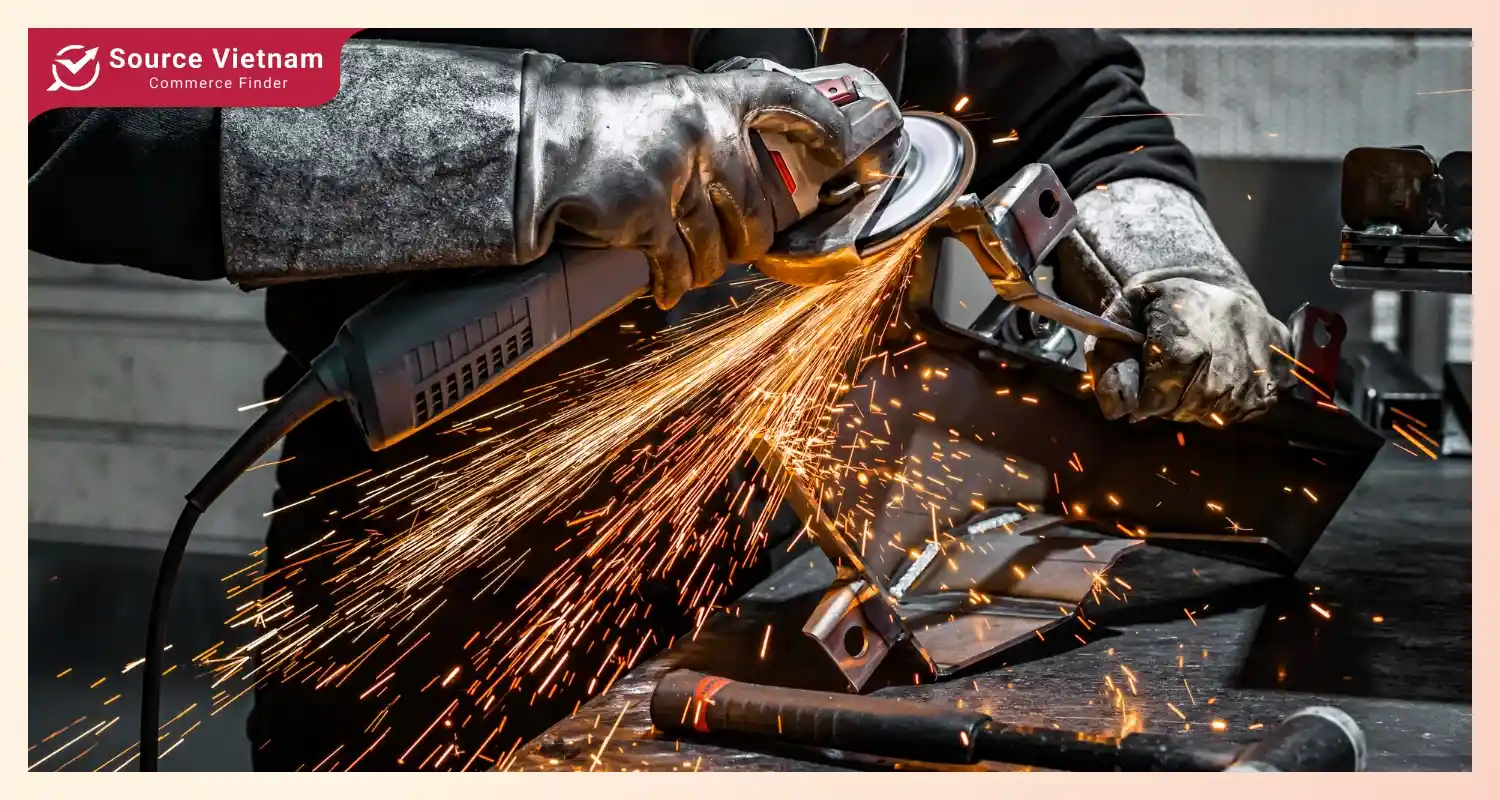

Today, companies are searching to enhance production capacity, cut down on costs, and ensure good service in this competitive environment. In this regard, the popularity of industrial robots cannot be stressed enough, but also, in this context – automated systems and other classes of technologies. Also, with the emergence of AI and the IoT, new proofs of “smart devices” are created, increasing the efficiency and productivity of intelligent devices that can learn, adapt, and self-correct on the manufacturing floor.

What is evident is that the American manufacturing industry is undergoing significant transformation changes. The recent and rapid emergence of new sectors like renewable energy or electric vehicles creates demand for certain types of equipment. Similarly, the situation where mass production was the only option is now being transformed, and machines are expected to be more flexible to adapt to customers’ unique standard product requirements.

Similarly, due to the increase in environmental issues, there are pressures for industries to shift production to more green processes. With these also comes the increased demand for energy-efficient and environmentally sustainable machinery and the increasing use of metals manufactured from scrap in industrial processes. These changes not only contribute to environmental preservation but also provide favorable economic prospects for industries in the long run.

Challenges of the industrial machinery market

The international market for industrial machinery is becoming competitive at an increasing rate. Globalization presents a mix of opportunities and challenges, especially with many competitors from around the globe. Additionally, the fast-changing technology landscape requires companies to innovate more, pushing them to regularly update and refine their offerings to address the diverse and unpredictable needs of the market.

The environmental and safety regulations are becoming very strict and increasing demands on the industrial machinery sector. Companies are forced to go green, reduce adverse environmental effects, and guarantee the safety of employees. This entails considerable expenditure on new technologies and modifications of production processes.

Changes in incorporated costs, especially the labor cost and the consumers’ demands greatly influence the cost of production and the profitability of businesses. More and more customers expect companies to offer them customized solutions that are eco-friendly and do not cost as much. Companies must, therefore, discover methods to enhance production technologies, diminish expenses, and increase the quality of the goods offered.

In addition to economic tensions and trade disputes, political factors also create considerable risk to the industrial machinery market. New technologies such as AI and IoT are also developing rapidly, creating risks and opportunities for industries. To respond to such changes, business organizations must enhance their research and development efforts and establish intelligent and automated systems explaining high investment purposes.

Conclusion

The growth aspects of the industrial machinery market are positive in all directions because of the rising automation, technology, and demand. The industry encounters various challenges, including strong competition, rigorous regulations, and rapid changes in consumer behavior. To tackle these constraints and achieve growth in this market, manufacturers should emphasize innovation, sustainable practices, and adaptability.

The companies’ long-term success can be achieved by adopting advanced technologies such as AI and IoT in operations while keeping energy and environmental concerns at the forefront.