Sustainable manufacturing is creating and applying production methods that are good for the environment, save money, and are fair to people. It reduces waste, saves energy and resources, and supports the health and safety of workers and communities.

With the rising concern for the environment, businesses confront a continuous push to go eco-friendly production. One potential resolution is sustainable production, permitting corporations to stay competitive while diminishing their environmental impact.

Today’s blog shows the fundamentals, advantages, and tactics of sustainable manufacturing, offering implementable perceptions for a greener future. The notion of what comprises sustainable production is examined further. Let’s get started!

What is sustainable manufacturing?

Industries are increasingly growing to meet the demands coming from the world. Sustainable production processes are fundamental to minimizing environmental impacts and preserving resources. But what, precisely, does sustainable manufacturing mean, and how is it changing the world?

Definition

Sustainable manufacturing is creating and applying production methods that are good for the environment, save money, and are fair to people. It reduces waste, saves energy and resources, and supports the health and safety of workers and communities.

Read more >>> What Does OEM and ODM Mean? Key Differences Explained

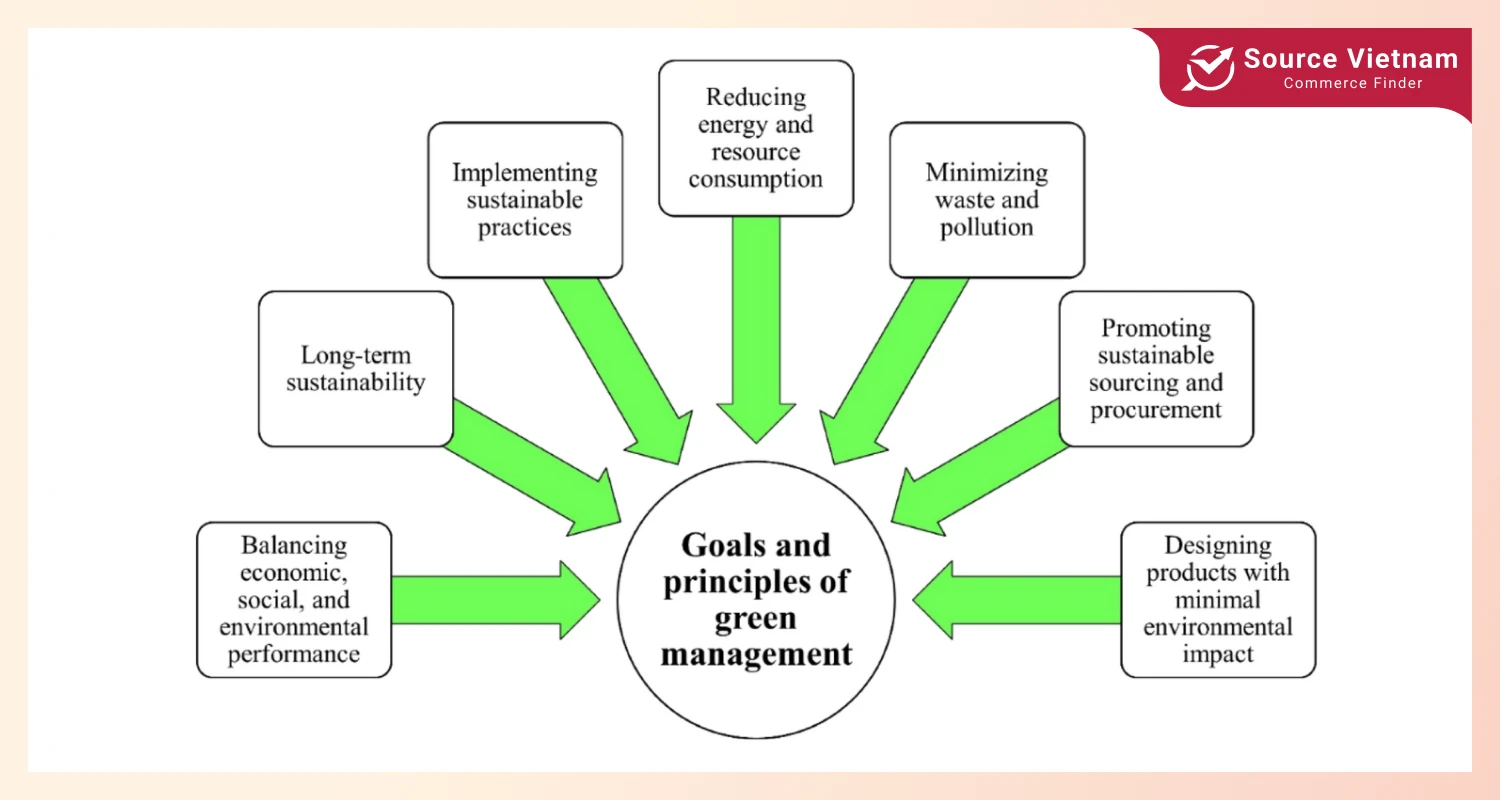

Principle of sustainable manufacturing

- Waste reduction and recycling: Pay attention to minimal waste and recycling to close the loops within the production chain.

- Energy efficiency: Better technologies and resource-efficient methods or practices to minimize usage but not at the cost of output production.

- Resources: To optimize raw materials during a production cycle to elongate the life span of such resources to avoid resource depletion

- Use of renewable materials: Finite resources must be replaced by renewable or biodegradable alternatives whenever feasible.

- Pollution prevention: Minimizing the level of emissions and pollutants throughout the lifecycle of production.

- Employee safety and well-being: Offer safe working conditions and improvement in the quality of life for employees.

By incorporating these principles into the processes, sustainable manufacturing will enable industries to handle environmental challenges and ensure economic and social advantages in the long run.

What is sustainable manufacturing and its importance?

The importance of sustainable manufacturing in modern industry

The need for sustainable practices is becoming more and more popular and important in our modern industry. So why does sustainable manufacturing matter? How does it help us tackle some of today’s biggest challenges? Let’s break it down!

Solving global challenges

- Reducing climate change: Sustainable manufacturing partly reduces greenhouse gas emissions using cleaner technologies and renewable energy. This helps to create a healthy environment and considerably reduces the effects of climate change.

- Economy of resources: Ever been concerned that someday we will be devoid of water, energy, and raw materials? Well, sustainable manufacturing protects these resources from being used up too fast.

- Keeping pollution in check: Reducing waste and emissions protects nature and ensures air, water, and soil will be clean enough for future generations.

Strengthen the business’s reputation

- Creating a positive image: Companies concerned about sustainability appeal to customers and investors alike. Showing that your enterprise is eco-friendly production can strengthen your reputation!

- Competitive advantage: Sustainability provides a competitive advantage to any company by enabling it to access new green markets or differentiate itself from competitors.

- Increase employee morale: People love working for companies that share their values. Sustainable production processes can make the employees proud and motivated, thus creating a happier workplace.

Though sustainable production benefits the environment, businesses boost their bottom lines, too. By facing lofty obstacles through green manufacturing, companies reinforce bonds and pave brighter paths ahead for all stakeholders.

Read more >>> Top 20 Best Wholesale Websites for Small Businesses in 2025

Benefits of sustainable manufacturing practices

Environmental benefits

Sustainable manufacturing reduces carbon footprints through energy-efficient manufacturing and renewable energy sources. These practices help minimize greenhouse gas emissions. In addition, it promotes the conservation of all water, energy, and raw material resources that will be important for future generations.

Another important feature is the reduction of waste. Most manufacturers try to recycle and reuse materials and optimize their processes for minimal waste. Besides, sustainable practices prevent pollution, restricting emissions that could harm air, water, and soil quality protecting ecosystems and biodiversity.

Economic benefits

Equally impressive are the economic benefits of sustainable manufacturing. Most businesses save a great deal of money by reducing energy consumption, minimizing waste disposal costs, and better utilization of resources. These measures reduce not only operational costs but also improve productivity.

Such businesses frequently engage locally, encouraging responsibility while lessening harmful environmental effects. Everyone benefits – companies, workers, neighborhoods, and the earth. It seeks balance holistically, inciting progress yet clearing a path toward a greener, sustainable tomorrow. Moreover, the focus extends beyond factories, as involvement in surrounding communities nurtures social conscience and minimizes negative externalities.

Social benefits

Socially, the benefits of sustainable manufacturing show up as meaningful workplace and community improvements. Focusing on employee health and safety, companies provide superior working conditions for happier, more engaged teams. Besides, sustainable businesses are often involved in local communities, fostering social responsibility and minimizing negative environmental impacts within their surroundings.

With sustainable manufacturing, everyone benefits: businesses, employees, communities, and the planet. It is holistic in driving for change while paving the way to a greener, more sustainable future.

Unlock the benefits of sustainable manufacturing.

Key considerations for businesses

Transitioning to sustainable manufacturing is a rewarding journey but also quite complex. It requires a lot of planning and collaboration for its success, with a focused emphasis on key areas that will drive meaningful change and long-term benefits.

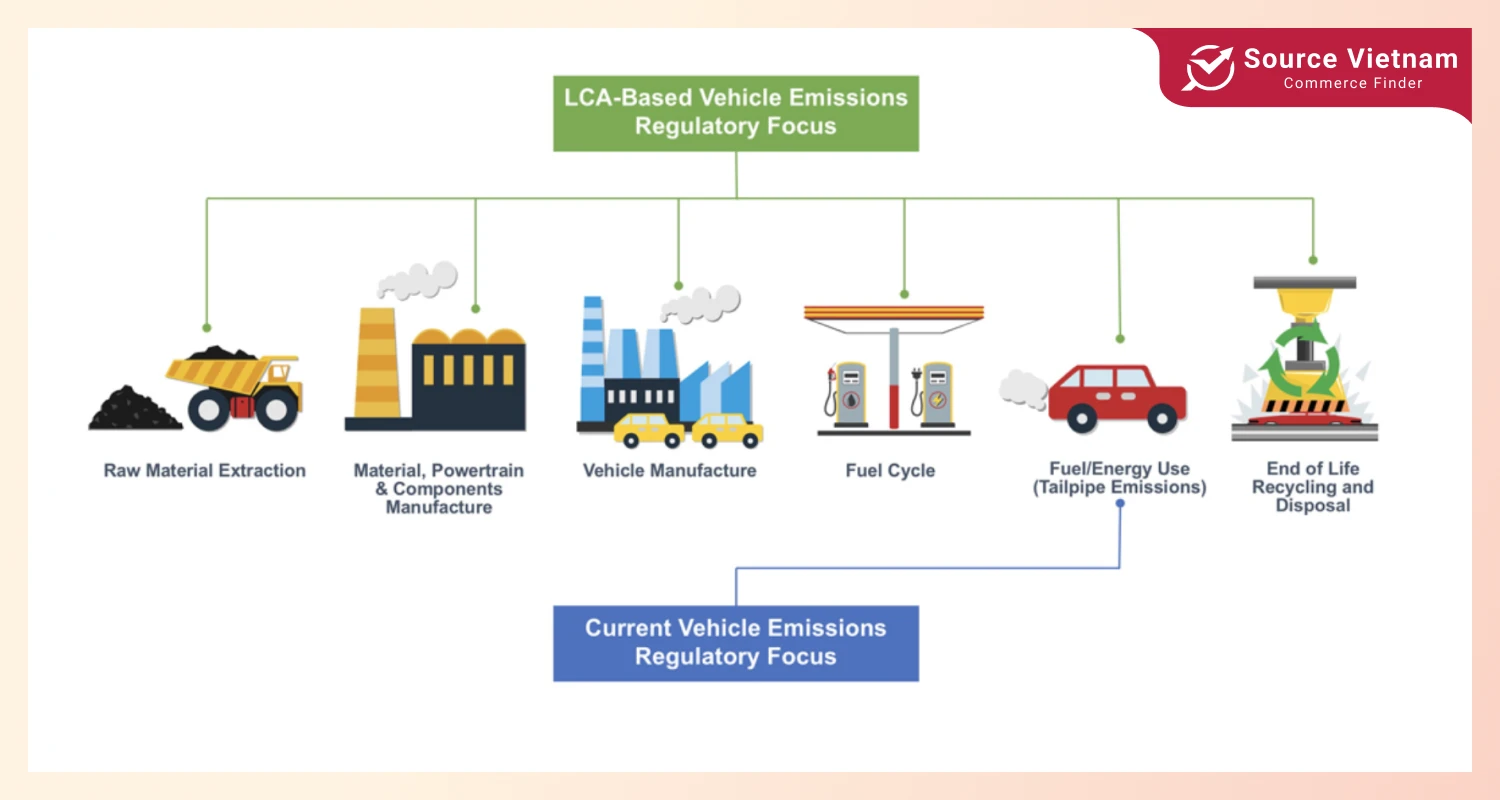

Assessing environmental impact

The first important thing is how your business measures the environmental impact of its operations. What and to what extent? Life cycle assessment (LCA) can help measure the environmental impacts of a product throughout its life cycle. It starts from the extraction of raw materials to the final disposal. This comprehensive approach identifies the biggest avenues for improvement.

Engaging all parties in the journey towards sustainability

Sustainability takes a village and cannot be achieved alone. Businesses must foster cooperation with suppliers, workforce, clientele, and communities to craft sustainability aims and propel communal advancement jointly. Continuous learning and collaboration across the entire supply chain are essential to make sustainability more than just a one-time initiative but a collaborative evolution.

Continuous improvement and innovation

Sustainability is not something to be dealt with once and for all; it is a process. Companies should set ambitious, realistic sustainability objectives and periodically monitor their performances. It will keep the focus and momentum going.

Besides goal-setting, innovation has an important role in developing new technologies and processes that contribute to sustainability. With a continuous improvement mindset, businesses can lead from the front in sustainable manufacturing practices.

How to implement sustainable manufacturing processes

Embracing sustainable practices is crucial for the industry’s future success. Here is a comprehensive yet successful guide to getting started on the path of sustainability:

- Assess current practices and set goals: A thorough review of current operations is the first step to differentiate wasteful processes from efficient ones. Streamlined methods and optimized equipment utilization can uncover pathways to environmental impact reduction. With quantifiable aims such as decreased energy consumption or reduced landfill outputs, a company can systematically chart a course to greener outcomes.

- Adopt lean manufacturing: Adopting lean production techniques removes the superfluous to concentrate solely on minimizing discarded materials.

- Implement a circular economy in manufacturing: When each phase of fabrication reuses and recycles what came before, whether parts or packages, a “circular” workflow emerges that durably sustains resources in closed loops.

- Utilize renewable energy sources: Tap into the sun’s power, wind, and other natural energy cycles to support operations and limit harmful emissions.

- Optimize resource efficacy: Conserve precious water, materials, and fuels through innovative technologies and practices that maximize efficiency and minimize waste.

- Reduce, reuse, recycle: Craft systems that lessen discarded outputs and boost recycling within business walls and farther afield. Seek closed-loop solutions where feasible.

- Engage workers, allies, and affected communities: Foster dynamic collaborations and shared commitments among employees, providers, and local populaces. Together, we seek sustainable pathways forward through open communication and cooperative problem-solving.

By these means, enterprises can sculpt greener, more effective processes and lead towards an environmentally sound future for all.

A step-by-step guide to implementing sustainable manufacturing

Advanced manufacturing technologies

With innovation being embraced in industries, advanced manufacturing technologies are changing how companies pursue sustainability. These modern solutions lower environmental impact while increasing efficiency and competitiveness.

- 3-D printing: This technology reduces waste using precise, additive manufacturing methods and allows for on-demand production, often with sustainable materials such as biodegradable plastics or recycled components.

- Artificial Intelligence (AI) and machine learning: Intelligent systems studying gigantic datasets in real-time tweak production protocols, decreasing energy utilization while boosting material efficiency. The Industrial Web connects various machines, sensors, and systems, transmitting crucial operational information wirelessly for ongoing observation and analytics. Consequently, businesses can pinpoint and resolve inefficiencies, refining energy-draining protocols or identifying wasteful motion in robots.

- Biotechnology: Biotechnological advances have allowed the production of environmentally friendly materials, such as bio-based plastics. In addition, sustainable production processes are based on natural methods.

- Sustainable manufacturing: The future of sustainable advanced manufacturing techniques

Challenges in adopting sustainable manufacturing practices

While sustainable manufacturing offers significant benefits, these practices bring many different challenges.

- Upfront costs: Implementing sustainable technologies and processes often requires huge initial investments. It can be a barrier for many businesses.

- Lack of expertise: The change to sustainable manufacturing requires specialized knowledge and skills. These may not always be readily available within an organization, so you can pay for more labor costs.

- Supply chain complexity: Combining sustainability with a supply chain involves coordinating with multiple stakeholders, which can become challenging.

- Measuring and reporting: This requires reliable metrics and robust data collection systems to execute exactly.

Overcoming the challenges of sustainable manufacturing

Conclusion

Sustainable manufacturing is far more than a preference; it’s now essential for enterprises hoping to prosper in an era that appreciates eco-consciousness. By embracing environmentally sound practices, businesses can lessen their footprint on the planet, optimize the usage of inputs, and cultivate closer bonds with interested parties. More so than a commercial tactic, it demonstrates a dedication to crafting a brighter path ahead for those still to come.

Toward sustainability: Manufacturing with tomorrow in mind!

If you are a business owner or have a passion for business, please visit SourceVietnam.com to assess your gross profit better.

FAQs about sustainable manufacturing

What are the advantages of sustainable manufacturing?

Sustainable manufacturing helps businesses reduce environmental impact and operational costs while enhancing their reputation by conserving scarce resources and promoting innovation. Transitioning to sustainable practices shows a company’s commitment to stewardship that resonates with consumers and communities.

How can I make my manufacturing process more sustainable?

To begin your sustainable manufacturing journey, carefully audit current operations to establish a baseline and identify high-impact areas for improvement. Then, set specific and measurable sustainability targets utilizing lean principles, circular economy designs, renewable energy sources, and resource-efficient technologies to minimize waste and emissions wherever practicable. Constantly evaluating innovations will help maximize sustainability’s environmental and financial benefits for years to come.

Some examples of sustainable manufacturing technologies?

You can refer to 3D printing for waste reduction, AI and machine learning for process optimization, IoT for real-time monitoring, and biotechnology for eco-friendly materials.

What are the challenges when implementing sustainable manufacturing?

Key challenges include upfront costs, lack of expertise, supply chain complexity, and difficulties in measuring and reporting.

What are the key principles of sustainable manufacturing?

The principles include waste reduction, energy efficiency, resource conservation, pollution prevention, use of renewable materials, and ensuring employee safety and well-being.

How can small businesses implement sustainable manufacturing practices?

Small businesses can start by optimizing energy use, reducing waste, sourcing eco-friendly materials, and collaborating with stakeholders to develop cost-effective, sustainable solutions.

What are the challenges in adopting sustainable manufacturing?

Adoption challenges include financial constraints, technical knowledge gaps, and coordinating sustainability efforts across complex supply chains.

How does sustainable manufacturing impact a company’s bottom line?

While initial costs may be high, sustainable manufacturing often leads to long-term savings through reduced energy use, waste management, and enhanced brand loyalty, ultimately improving profitability.