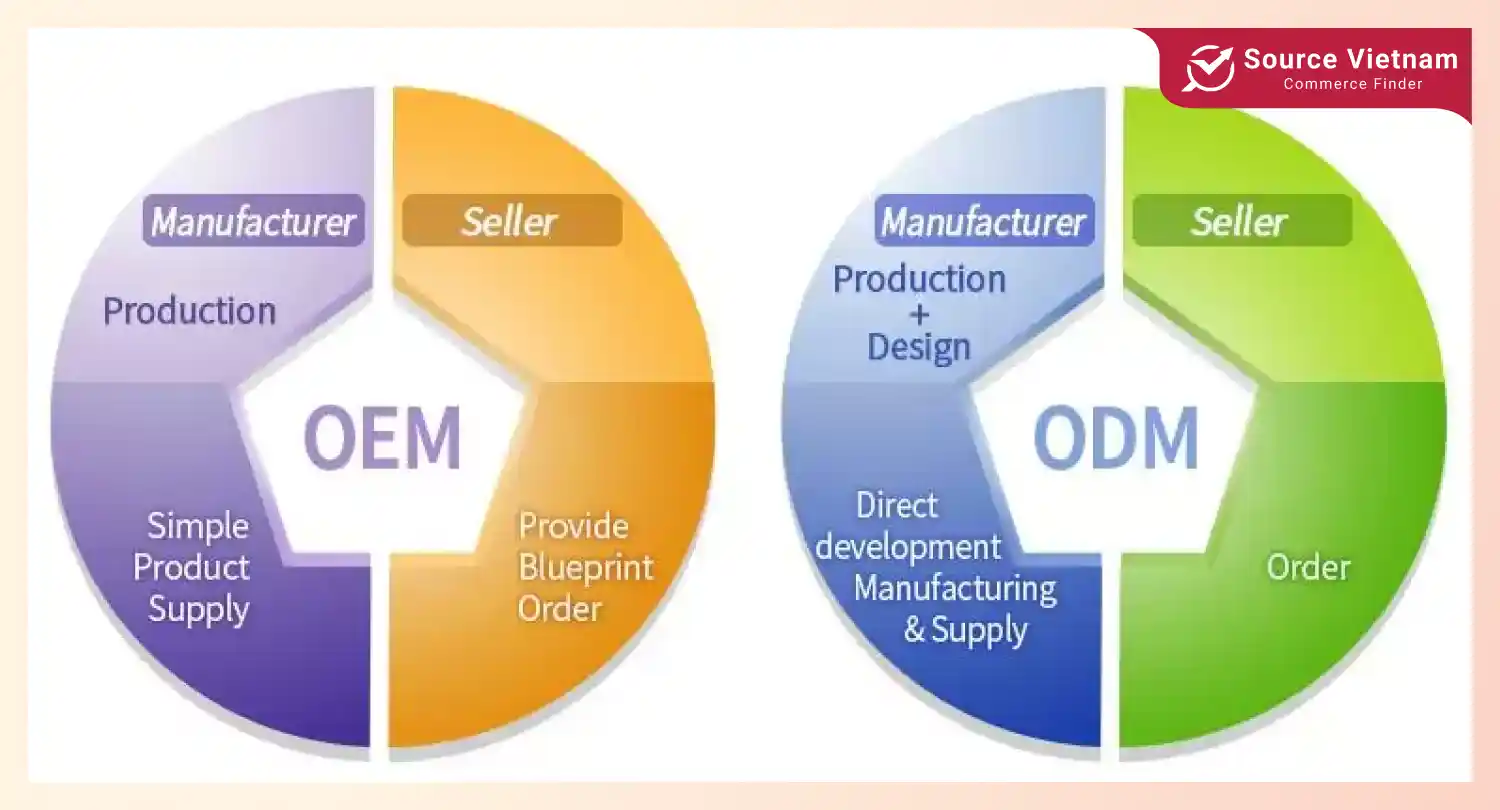

OEM produces products based on clients’ designs, while ODM handles design and manufacturing. The choice depends on a company’s need for control, customization, cost, and speed.

There is considerable debate about the distinctions between these models and which of the seven was the most effective. But what does OEM and ODM mean?

Manufacturing often revolves around two key business models: OEM and ODM. The terms OEM ODM meaning in business, are sometimes regarded as interchangeable but not. OEMs produce products clients create according to documented specifications, while ODMs do most or all the designing themselves.

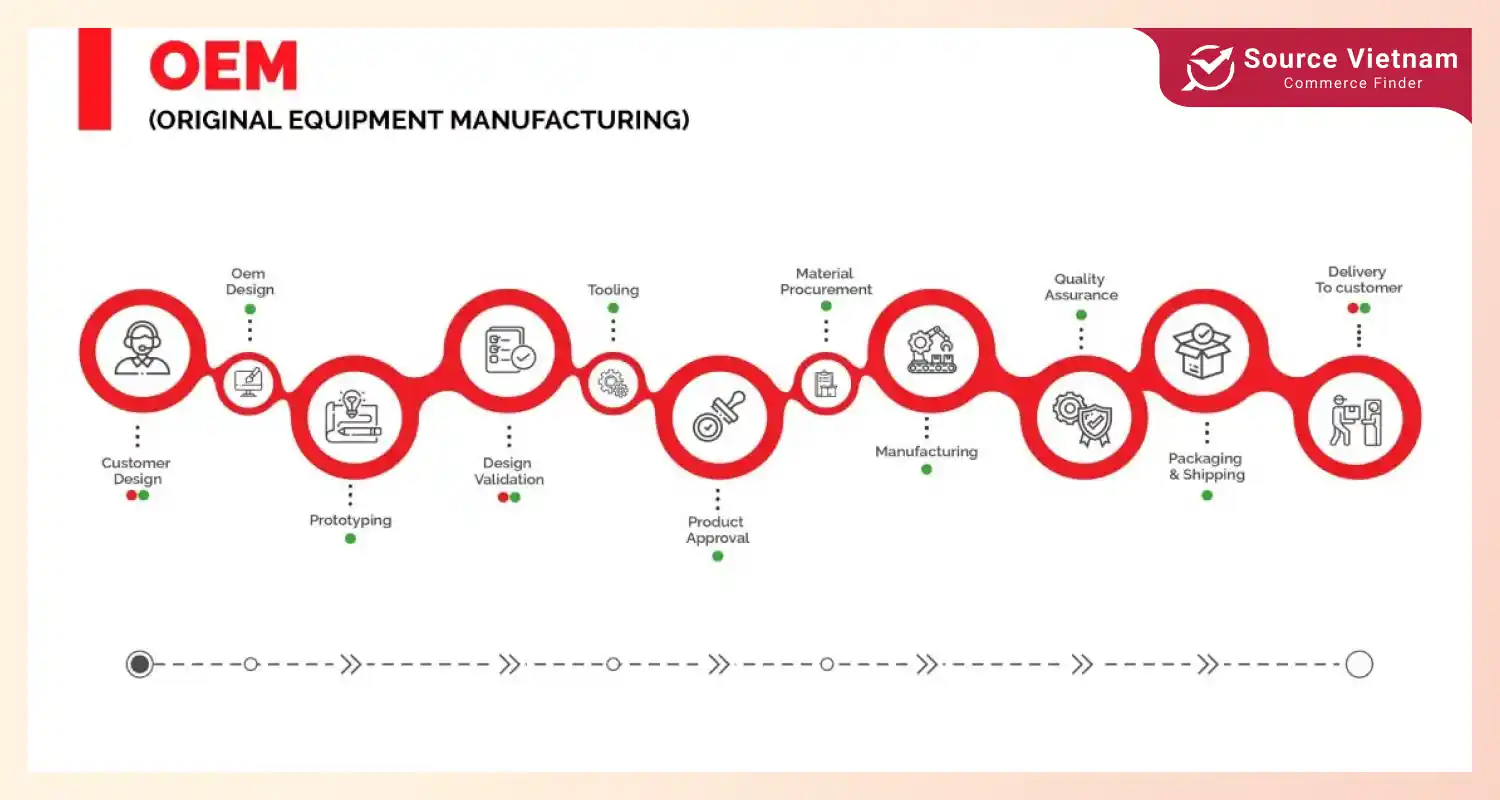

What is OEM in manufacturing?

OEMs (Original Equipment Manufacturers) produce products designed not in their organizations but by other companies, the brand owners. The OEM handles the material supply, manufacturing effort, assembly, and quality checks.

The method allows the brand owner to focus on marketing and sales, leveraging their brand recognition. The OEM, in turn, benefits from the brand’s established market presence. This collaboration ensures the final product aligns with the brand’s vision and quality standards.

Foxconn is an example of an OEM as it makes Apple. And Bosch is also an OEM that sells automotive parts to vehicle manufacturers. These OEMs exhibit how companies concentrate on production, relieving brands to handle design and marketing issues.

Successful OEM relationships rely on comprehensive agreements that clearly define the responsibilities of both the brand and the manufacturer. These contracts have all the details of how IP will be handled, the number of units produced, the quality, and the pricing. An original equipment manufacturer agreement is legitimized, guaranteeing that the necessities regarding business dealings are taken care of. To prevent any form of operating risk while ensuring that the parties remain in a healthy business relationship and deliver qualified products to the market.

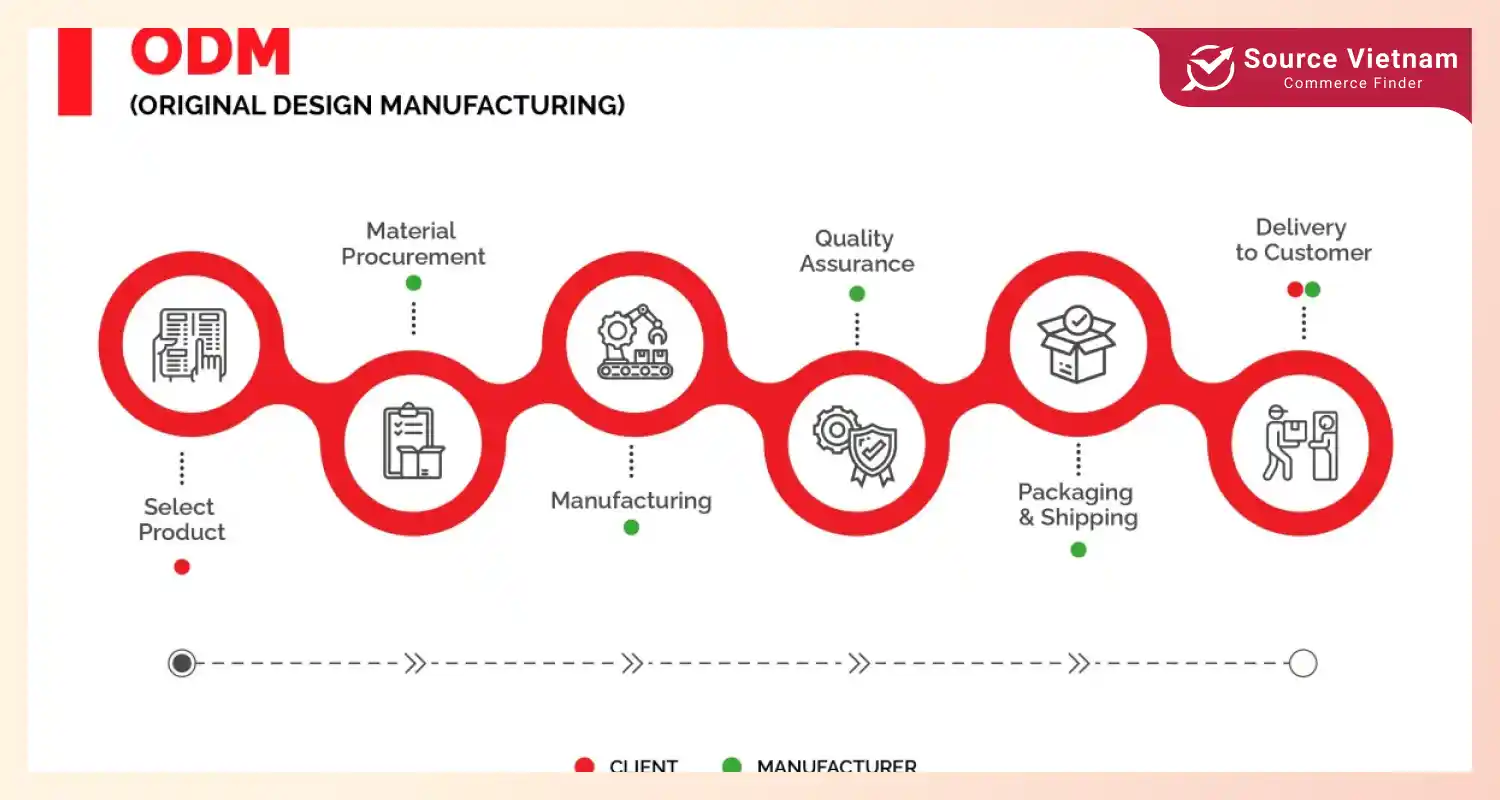

What Does ODM Stand For?

ODM stands for Original Design Manufacturer. Unlike OEMs, ODMs handle both the product design and the manufacturing. They have the in-house expertise to create a product from scratch and then produce it efficiently. The company that commissions the product essentially gets a ready-made solution, taking care of the branding and sales while the ODM operates behind the scenes.

For example, ODMs like Compal Electronics and Quanta Computer are the masterminds behind many popular laptops. They handle the design and production elements, enabling other brands like HP and Dell to emphasize marketing, promoting, and selling the product. Thereby allowing companies to do what they know best and depend on ODMs for their unique approaches in a dynamic industry.

Read more: What Does MOQ Mean in Manufacturing and Business?

Distinction factors between ODM and OEM

OEM and ODM manufacture differently, which affects many factors. A careful examination of these key differences will empower an informed decision-making process.

| Feature | OEM | ODM |

| Design and development | OEM manufactures based on designs provided by the client | ODM handles all design and development in-house |

| Intellectual property | The client owns the design and IP | ODM typically owns the design and IP |

| Customization | High level of customization possible to meet specific client needs | Limited customization options, often based on existing ODM designs |

| Cost | Can have higher initial costs due to custom design and tooling | Generally lower upfront cost due to existing designs and streamlined production |

| Time to market | Longer time to market because of design and development phases | Faster time to market due to readily available designs |

| Control | The client has greater control over the final product’s specifications and branding. | ODM has greater control over the design and manufacturing process |

Design and development

- OEM: The company client provides the complete product design, including specifications, materials, and functionality. The OEM takes responsibility for creating the product according to the supplied specifications.

- ODM: performs the design work and also manufactures the product. ODMs also have a stock of pre-made designs from which companies can choose and potentially modify.

Intellectual property

- OEM: The company owns the product’s design and all associated intellectual property. This gives complete control over the product and its future development.

- ODM: The ODM typically owns the intellectual property rights to the initial design. However, a company can often negotiate exclusive rights to use that design for their product.

Customization

- OEM: Customization might be limited to minor tweaks and modifications to the existing design. Significant changes could require a new manufacturing process.

- ODM: Generally offers more flexibility to customize and modify their existing designs to better align with a company’s needs and branding.

Cost

- OEM: Prices fluctuate based on the complexity of the design, the materials and the amount of capital required for manufacturing.

- ODM: This model is generally cheaper since a company does not have to spend on the first design and development phase. The ODM absorbs those costs.

Time to market

- OEM: If a finalized design is ready for production, OEM can be a faster route to market.

- ODM: The ODM model might have a longer lead time as they go through their design and development process, even if it’s based on an existing design.

Control

- OEM: A company controls the product’s design, features, and overall specifications.

- ODM: The ODM has more control over the manufacturing process and the core elements of the initial design. A company has less influence over these aspects.

Read more: What Is Contract Manufacturing? A Complete Guide for 2025

Advantages and disadvantages of OEM and ODM

Companies should understand the benefits and limitations of OEM and ODM. They are not the same; however, they are both equally relevant in offering a business a range of disadvantages and advantages. Let’s consider the difference between ODM and OEM before implementing them.

OEM

Advantages:

- Brand control enables strong brand differentiation as you control the product’s design and specification.

- Quality control: You might have more control over the production quality and demand the factory produces according to your standards.

- Faster time-to-market: You can minimize the time needed to rush the production of a finalized product ready for selling.

Disadvantages

- Higher upfront costs: required a lot of money in market research, product design and product development before starting the manufacturing.

- Manufacturing expertise: This is ideal for organizations with a dedicated manufacturing unit or for those who can find trustworthy OEM partners willing to take on the job.

- Limited customization: This requires the ability to re-engineer the design before finalization, as changing significantly the product after the design has great restrictions.

ODM

Advantages:

- Cost-effectiveness: First and foremost, all the designing and developing tasks are performed by ODM, thus saving you an enormous amount of money.

- Access to expertise: insurance claims are easier or cheaper to resolve when you have the ODM design and manufacture for you, especially in cases when the internal capabilities are pretty limited.

- Faster product development: Rather, the existing designs of the ODM are utilized, and the working methods needed to produce these new designs are created to shorten the market entry time for the product and increase efficiency.

- Focus on branding and sales: ODM executes the production processes. The business outsourcing strategies allow companies to stretch marketing and sales, brand building, and target markets.

Disadvantages:

- Less design control: You might have limited input on the initial product design, relying on the ODM’s existing designs and expertise.

- Intellectual property concerns: Establishing clear intellectual property ownership agreements with the ODM to protect your brand and product is essential.

- Potential quality variations: May face challenges in ensuring consistent product quality, especially when working with multiple ODM partners or across different production batches.

OEM vs. ODM: Which is right for your business?

Selecting the optimal manufacturing model, whether what OEM/ODM means, hinges on a careful evaluation of your business goals and resources.

- Business goals & priorities: Do you need to get to market quickly? Is cost your primary concern? Or do you want complete control over your product’s design and branding? These factors will heavily influence whether OEM or ODM is the better fit.

- Product complexity & design: How complex is your product? Do you have the designer in-house, or would you benefit from an ODM’s design capabilities?

- Resources and capabilities: Do you have a strong in-house design team? What about manufacturing connections and experience with supply chain management? If not, an ODM might be a better fit.

- Risk tolerance: How much risk are you comfortable with regarding intellectual property ownership and potential manufacturing challenges? OEMs often provide more control and security in these areas.

Case studies

Foxconn

Based in Taiwan, Foxconn Technology Group is often considered the biggest electronics manufacturer in the world. With numerous factories in mainland China, Foxconn’s business model is based on contract manufacturing and supplying a comprehensive service to some of the biggest tech corporations.

The extraordinary capability covers a wide range of products, from smartphones and computers to gaming consoles and televisions. Foxconn owes its meteoric rise in the industry to its role as a main partner of Apple – they mostly assemble phones for this company. Due to this OEM relationship, Foxconn has supplied its sheer size and operating efficiency to the market. They become a dominant force in the electronics manufacturing industry.

Xiaomi

Xiaomi Corporation is a Chinese company which involved in electronics and software manufacture. They have made a fascinating entry into the global market, especially regarding smartphones and consumer electronics. The company was founded in the year 2010 and came up with an innovative business approach that heavily depended on ODM’s.

Instead of manufacturing products in-house, the company contracts them out to specialized partners and concentrates on product design, software development, and marketing. This strategy has empowered them to be able to have a large number of products at relatively lower prices, enabling them to grow and expand into new regions faster. Sparing the available ODM model in China seems to be the purpose of most companies willing to increase revenues through product development and gain a competitive edge.

Conclusion

In the manufacturing space, expansion will definitely require clarity regarding the differences between OEM and ODM. But what does OEM and ODM mean in practice?

Choosing the right approach depends entirely on your specific needs and priorities. Whether you prioritize control over design with an OEM or seek a streamlined solution with an ODM, making an informed decision is key to optimizing your manufacturing strategy.

FAQs

Why do businesses prefer ODM?

Many advantages are associated with an ODM, especially for businesses that want to make their operations more efficient and cut back on costs. With someone standing as the designer and manufacturer, a firm can greatly reduce the time to market. At the same time, ODMs usually have developed logistics and production chains, enabling them to save time. This means businesses can concentrate on branding, marketing, key accounts, and sales on their end, while the ODM has to deal with the burden of product design and manufacturing.

What has to be paid attention to in an OEM agreement?

The purchasing company and the contracted manufacturer must be on the same page from an OEM perspective. These focal points include intellectual property, volumes of production, quality of products, pricing agreements, and delivery terms. Well-formulated OEM instinctively shields both parties and makes cooperation smooth and successful.

For startups, which of the manufacturing models is more reasonable?

The ODM model is often more reasonable. With ODM’s being responsible for creating and constructing a product, the need for a large sunk cost from the startup is eliminated. Thus, such firms can focus on key activities such as promotion and selling.

When is it advantageous for a company to use OEM instead of ODM?

In cases when businesses have the original version of a product and want to have an oversight of its making, they should consider subscribing to the OEM model. This applies particularly to those with strong brand identity and stringent quality specifications.

Is it possible to shift from using an OEM model to an ODM model in a company?

Certainly, companies can shift from using an ODM and an OEM model. Linkages among such factors as business requirements, product plans, and changes in the market environment usually influence this decision. A business utilizes a shift to acquire different technologies, manage costs better, or have more flexibility in the product development cycle.